Semiconductor devices. The rapid development and expansion of the fields of application of electronic devices is due to the improvement of the element base, - presentation. Semiconductor properties and their application. presentation for a lesson in physics (grade 10) on t

Presentation "Temperature measuring instruments"

The presentation contains a classification of temperature measuring instruments by contact and non-contact methods. The principles of operation of a manometric thermometer, resistance thermometer, thermoelectric thermometer, pyrometer are stated. Typical temperature measuring devices used at industrial enterprises are considered

This presentation can be used in the study of theoretical material on the discipline "Automation of technological processes" for the specialty 270107 "Production of non-metallic building products and structures"

The presentation posed the following questions:

1 temperature measurement

2 temperature measurement by contact method

3 gauge thermometers

4 electrical resistance thermometers

5 thermoelectric thermometers (thermocouples)

6 intelligent temperature transmitters

7 digital thermometers small

8 Non-contact temperature measurement

9 pyrometers

10 universal temperature measurement system

11 non-contact infrared sensors

12 single color pyrometers

13 ratio pyrometers

14 fiber optic ratio pyrometers

15 Questions for self-control.

This presentation is made in accordance with the requirements for the results of mastering disciplines and work programs in the specified specialties

Download:

Preview:

To use the preview of presentations, create yourself a Google account (account) and log into it: https://accounts.google.com

Slide captions:

Temperature measuring instruments. NKSE teacher N.V. Krivonosova

contents 1 Temperature measurement 2 temperature measurement by contact method 3 pressure thermometers 4 electrical resistance thermometers 5 thermoelectric thermometers (thermocouples) 6 smart temperature transducers 7 small digital thermometers 8 Non-contact temperature measurement 9 pyrometers 10 universal temperature measurement system 11 non-contact infrared sensors 12 one-color pyrometers 13 pyrometers spectral ratio 14 fiber optic ratio pyrometers 15 questions

Temperature measurement Instruments for temperature measurement are divided into two groups: - contact - there is a reliable thermal contact of the sensitive element of the device with the object of measurement; - non-contact - the sensitive element of the thermometer during the measurement process does not have direct contact with the measured medium

Contact temperature measurement Classification according to the principle of operation: 1. Expansion thermometers - the principle of operation is based on the change in the volume of a liquid (liquid) or linear dimensions of solids (bimetallic) with a change in temperature. Measurement range from minus 190 ° С to plus 600 ° С.

2. Manometric thermometers - the principle of operation is based on a change in the pressure of liquids, a vapor-liquid mixture or gas in a closed volume when the temperature changes. Measurement ranges from minus 150 ° С to plus 600 ° С. Contact temperature measurement

Contact temperature measurement 3. Electrical resistance thermometers - based on the change in the electrical resistance of conductors or semiconductors when the temperature changes. Measurement limits from - 200 ° С to + 650 ° С.

Temperature measurement by contact method 4. Thermoelectric converters (thermocouples) - based on the occurrence of thermoelectromotive force when heating the junction of dissimilar conductors or semiconductors. Temperature range from - 200 ° С to + 2300 ° С.

Gauge thermometers Gauge thermometer with tube spring

Manometric thermometers The dependence of pressure on temperature has the form where \u003d 1 / 273.15 - temperature coefficient of gas expansion; t 0 and t - initial and final temperatures; Р 0 - pressure of the working substance at temperature t 0. P t \u003d P o (1 + β (t - to))

Electrical resistance thermometers Platinum resistance thermometers (RTC) are made for temperatures from –200 to +650 0 С and copper resistance thermometers (TCM) for temperatures from –50 to +180 0 С.

Electrical resistance thermometers Semiconductor resistance thermometers, called thermistors or thermistors, are used to measure temperatures in the range from –90 to +180 ° C.

Electrical resistance thermometers Instruments that work with resistance thermometers: - balanced bridges, - unbalanced bridges, - ratiometers.

thermoelectric thermometers (thermocouples) The junction of a thermocouple with a temperature t 1 is called hot or working, and a junction with t 0 is called cold or free. Thermocouple thermoEMF is a function of two temperatures: E AB \u003d f (t l, t 0).

thermoelectric thermometers (thermocouples) Electrical diagram of the thermoelectric converter (thermocouple)

thermoelectric thermometers (thermocouples) Instruments that work with thermocouples: - magnetoelectric millivoltmeters; - automatic potentiometers.

thermoelectric thermometers (thermocouples) standard thermocouple graduations

thermoelectric thermometers (thermocouples) Thermal converters with a unified output signal ТХАУ Metran - 271, TSMU Metran - 74

thermoelectric thermometers (thermocouples) THAU Metran - 271, TSMU Metran - 74 The sensing element of the primary transducer and the measuring transducer built into the sensor head convert the measured temperature into a unified current output signal, which makes it possible to build an automated process control system without the use of additional normalizing converters

thermoelectric thermometers (thermocouples) THAU Metran - 271, TSMU Metran - 74 The use of thermocouples is allowed in neutral and corrosive environments, in relation to which the material of protective fittings is corrosion-resistant

Intelligent temperature transmitters Metran - 281 Metran - 28 6

Intelligent temperature transducers Intelligent temperature transducers (IPT) Metran-280: Metran-281, Metran-286 are designed for accurate temperature measurements of neutral, as well as aggressive media in relation to which the material of protective fittings is corrosion-resistant.

Intelligent temperature converters The IPT is controlled remotely, while the sensor is configured: - selection of its main parameters; - readjustment of measurement ranges; - request for information about the IPT itself (type, model, serial number, maximum and minimum measuring ranges, actual measuring range).

Intelligent temperature converters Metran-280 has three temperature measurement units: - degrees Celsius, º С; - degrees Kelvin, K; degrees Fahrenheit, F. Range of measured temperatures from 0 to 1000 ºC.

Intelligent temperature transducers Structurally, Metran-280 consists of a temperature probe and an electronic module built into the body of the connection head. Sensitive elements made of a thermocouple cable KTMS (XA) or resistive sensitive elements made of platinum wire are used as a primary thermal converter.

Intelligent Temperature Transmitters When a fault is detected in self-diagnosis mode, the output is set to the low (I out ≤ 3.77 mA) alarm. Metran-280 implements a protection mode for sensor settings from unauthorized access.

Compact digital thermometers TCM 9210

Small-sized digital thermometers TCM 9210 thermometers are offered to replace liquid glass thermometers (mercury, etc.). TCM 9210 provide a clear indication of temperature in low light conditions.

Small-sized digital thermometers Small-sized digital thermometers TCM - 9210 are intended for measuring the temperature of bulk, liquid and gaseous media by immersing thermal converters into the medium (immersion measurements) or for contact measurements of surface temperatures (surface measurements) with the presentation of the measured temperature on the digital display of the electronic unit.

Small-sized digital thermometers Thermometers are used in scientific research, in technological processes in the mining, oil, wood-processing, food and other industries. The range of measured temperatures is from - 50 to +1800 ºC.

Small-sized digital thermometers Thermometers consist of a thermal converter (TTC), an electronic unit and a power supply unit. TTC consists of a sensitive element (SE) with a protective sheath, internal connecting wires and external leads that allow connection to the electronic unit of the thermometer.

Small-sized digital thermometers As a CHE in TTC thermometers, resistance temperature converters Pt100, thermoelectric converters TXA (K) are used. The electronic unit is designed to convert the signal coming from the output of the TTTs into a signal of measuring information, which is displayed on a digital display.

Non-contact Temperature Measurement Non-contact devices include radiation pyrometers: 1. Partial radiation pyrometers (brightness, optical) based on changes in the intensity of monochromatic radiation of bodies depending on temperature. Measurement range from 800 to 6000 º С.

Non-contact temperature measurement 2. Radiation pyrometers - based on the dependence of the radiation power of a heated body on its temperature. The limit is from 20 to 2000 º С.

Non-contact temperature measurement 3. Color pyrometers - based on the dependence of the ratio of radiation intensities at two wavelengths on body temperature. Measurement ranges from 200 to 3800 º С.

pyrometers Portable pyrometers ST20 / 30Pro, ST60 / 80ProPlus

pyrometers Portable pyrometers ST20 / 30Pro, ST60 / 80ProPlus Fast, compact and lightweight pistol-type pyrometers provide non-contact accurate temperature measurements of small, harmful, hazardous and hard-to-reach objects, are simple and easy to use.

pyrometers Portable pyrometers ST20 / 30Pro, ST60 / 80ProPlus Measured temperature range from - 32 to +760 ºC. The error ranges from -32 to +26 ºC. Sight: laser. Spectral sensitivity: 7 - 18 microns. Response time: 500 ms. Indicator: LCD with backlight and resolution; 0.1 º C ST60Pro. Ambient temperature: 0 - 50 0 C.

pyrometers Raynger 3i

raynger 3i pyrometers - a series of non-contact infrared pistol-type thermometers with precise sighting, with wide measuring ranges, various optical and spectral characteristics, a wide variety of functions, which allows you to choose a pyrometer in accordance with its purpose

pyrometers Raynger 3i - 2M and 1M (high-temperature models) - for foundry and metallurgical production: in the processes of refining, casting and processing of cast iron, steel and other metals, for chemical and petrochemical production; - LT, LR (low temperature models) - for temperature control in the production of paper, rubber, asphalt, roofing material.

pyrometers The Raynger 3i series pyrometers provide: - memory for 100 measurements; - alarm of the upper and lower measurement limits; - microprocessor-based signal processing; - access to a computer, recorder, portable printer; - compensation for reflected background energy.

raynger 3i pyrometers For model LT, LR the range of measured temperatures is from - 30 to + 1200 º C, spectral sensitivity is 8 - 14 µm. For model 2M the range of measured temperatures is from 200 to 1800 º C, spectral sensitivity is 1.53 - 1.74 µm.

Universal temperature measuring system THERMALERT GP

The Thermalert GP Universal Temperature Measurement System is a universal continuous temperature measurement system that includes a compact, inexpensive monitor and GPR and GPM infrared sensor. If required, the monitor is equipped with a relay module for two-point alarms and also provides power to the sensor.

Universal Temperature Measurement System Infrared sensors are needed in areas where contact temperature measurement will damage surfaces, such as plastic sheeting or contaminate the product, and for measuring the temperature of moving or hard-to-reach objects.

Universal temperature measurement system In thermalert GP series pyrometers: - monitor and sensor parameters are set from the monitor keyboard; - processing of measurement results is provided: fixation of peak values, calculation of average temperature, compensation of ambient temperature; - standard or focal optics are provided;

Universal temperature measurement system - alarm ranges are set by the operator; - it is possible to operate the GP monitor with other infrared pyrometers from Raytek, for example Thermalert Cl and Thermalert TX. The range of measured temperatures is from - 18 to + 538 º0 C.

Non-contact infrared sensors THERMALERT

Non-contact infrared sensors Stationary non-contact infrared sensors of the Thermalert TX series are designed for non-contact temperature measurement of hard-to-reach objects and are connected via a two-wire communication line to a monitor, for example, Thermalert GP

Thermalert TX non-contact infrared sensors For the LT model, the measured temperature range is from - 18 to + 500 º C, spectral sensitivity is 8–14 µm. For the LTO model, the measured temperature range is from 0 to 500 º C, spectral sensitivity is 8 - 14 µm. For MT model, the range of measured temperatures is from 200 to 1000 º C, spectral sensitivity 3, 9

Single color pyrometers Marathon MA

Ratio Pyrometers Marathon MR1S

Marathon MR 1 S Ratio Pyrometers The Marathon MR 1 S series stationary Ratio Pyrometers use a two-color measurement method to achieve high accuracy in high temperature applications. The MR1S pyrometers have improved electro-optical system, "smart" electronics, which are housed in a rugged, compact housing.

Spectral Ratio Pyrometers Marathon MR 1 S These pyrometers are the ideal solution for measuring temperature in gaseous, smoky areas, moving objects or very small objects, therefore they are used in various industries: smelting ore, smelting and processing metals, heating in various types of furnaces, including induction, crystal growing, etc.

Spectral Ratio Pyrometers Marathon MR 1 S pyrometers provide: - one - or two-color measurement mode; - variable focal length; - high-speed processor; - software for "field" calibration and diagnostics; - unique warning about "dirty" lens; Marathon DataTemp software.

Spectral Ratio Pyrometers For model MR A1 S A the range of measured temperatures is from 600 to 14 00 º C. For model MR A1 SC the range of measured temperatures is from 1000 to 3000 º C.

Marathon Fiber Optic Ratio Pyrometers

Fiber Optic Ratio Pyrometers Stationary Marathon FR1 series pyrometers use infrared spectral ratio technology, which provides the highest measurement accuracy in the range from 500 to 2500 0 C. Pyrometers allow you to measure objects in hazardous and corrosive areas, and are especially used where it is impossible to use others infrared sensors.

The Marathon FR1 Fiber Optic Ratio Pyrometers are capable of accurately measuring the temperature of hard-to-reach objects in high ambient temperatures, polluted atmospheres or strong electromagnetic fields.

questions What are the means of measuring temperature by the contact method? What are the non-contact temperature measuring instruments? What is the principle of a manometric thermometer based on? What is the principle of a thermoelectric thermometer based on? How does a pyrometer work?

resources http://kipia.ru/ http://www.thermopribor.com/ http://www2.emersonprocess.com/ http://hi-edu.ru/ http://www.omsketalon.ru/

Thanks for attention

To use the preview of presentations, create yourself a Google account (account) and log into it: https://accounts.google.com

Slide captions:

physics teacher: Abramova Tamara Ivanovna MBOU "Buturlinovskaya secondary school" 2016

What is a semiconductor? Where did the electrons and holes come from? What happens when you add arsenic to germanium? Semiconductors make contact. One-way conduction - not just on the roads. Diodes, transistors, LEDs, photocells - where do we meet them? Today in the lesson.

SEMICONDUCTORS ρ metals ‹ρ semiconductors ‹Ρ die. ρ₁ - CS of metals Ρ ₂ - CS of semiconductors Ρ ₃ - CS of dielectrics

Semiconductor structure Semiconductors include the chemical elements germanium, silicon, selenium, arsenic, indium, phosphorus, ... and their compounds. In the earth's crust, these compounds reach 80%. At low temperatures and in the absence of illumination, pure semiconductors do not conduct electric current, since they do not have free charges. Silicon and germanium each have 4 (valence) electrons on the outer electron shell. In a crystal, each of these electrons belongs to two neighboring atoms, forming, so-called. covalent bond. These electrons are involved in thermal motion, but remain in place in the crystal. S e R a Se l n Silicon

Intrinsic conductivity of semiconductors P r and n and grev and Pr and about lightening and N el. \u003d N holes.

semiconductor foil housing insulator terminal

Artificial Earth satellites, spaceships, electronic computers, radio engineering, automated counting, sorting, quality control systems, ... Application Photo relay, emergency switches.

impurity conductivity of semiconductors N electrons\u003e N holes Conductivity - electron (donor). Semiconductor - n-type. N holes\u003e N electrons. The conductivity is hole (acceptor). Semiconductor - p-type.

Electron - hole transition R zap. the layer is great! R s. decreased. R s. increased. d \u003d 10 ¯⁵ s m

Contact property of semiconductors with different types of conductivity n - p junction Characteristics The main property of the n - p junction - One-sided conductivity Voltamper Direct junction. Reverse transition

Germanium - cathode Indium - anode Semiconductor diode Main property - unilateral conductivity. It is used to rectify weak currents in radios, televisions, and strong currents in ED trams, electric locomotives.

The principle of operation of a semiconductor device Major charge carriers Minor charge carriers Types of diodes - planar and point. Advantages: Small size and weight, high efficiency, durable.

transistors They are used as amplifiers in radio engineering, in electrical engineering.

Semiconductor devices

Photocells and thermocouples

Application of photocells

Semiconductor LEDs LEDs are devices that convert electrical energy into light. Light quanta are emitted under the action of an applied voltage.

Semiconductor thermocouples Convert internal energy into electrical energy.

1. What carriers of electric charge create current in metals and in pure semiconductors? A. Both in metals and in semiconductors, only electrons. B. In metals only by electrons, in semiconductors only by "holes". C. In metals only electrons, in semiconductors electrons and "holes". G. In metals and semiconductors by ions. 2. What type of conductivity prevails in semiconductors with impurities? A. Electronic. B. Hole. B. Equally electron and hole. G. Ionic. 3. How does resistance depend on temperature in metals and semiconductors? A. In metals, it increases, and in semiconductors, it decreases with increasing temperature. B. In metals it decreases, and in semiconductors it increases with increasing temperature. B. In metals does not change, but in semiconductors decreases with temperature. D. In metals, it increases with temperature, and in semiconductors does not change. 4. Does Ohm's law apply to currents in semiconductors and metals? A. For current in semiconductors it is used, but not for current in metals. B. For current in metals it is used, but not for current in semiconductors. B. It is used for current in metals and for current in semiconductors. D. Not applicable in any case. Tasks for self-control 1.C 2.A 3.A 4.B.

On the subject: methodological developments, presentations and notes

When developing a lesson on the topic “Semiconductors. Impurity semiconductor. Self-Conductivity ”, electronic educational resources were used ....

development of a lesson on the topic "Semiconductors. Intrinsic and impurity conductivity of semiconductors. Electric current in semiconductors "...

presentation "Semiconductors. Intrinsic and impurity conductivity of semiconductors. Electric current in semiconductors"

presentation: "Semiconductors. Intrinsic and impurity conductivity of semiconductors. Electric current in semiconductors" ...

Non-contact temperature sensors (pyrometers)

used where access to the measured parts is difficult, and where mobility and low inertia of measurements are required. In addition, non-contact temperature sensors are irreplaceable where it is necessary to measure high temperatures - from 1500 to 3000 C.

Infrared radiation with a wavelength of 3-14 microns from the measured object enters the sensitive element of the non-contact temperature sensor and is converted into an electrical signal, which is then amplified, normalized, and in new models of sensors and digitized for transmission over the network.

The main areas of application of high-temperature pyrometers S-700.1 STANDARD:

Metallurgy: Temperature measurement of ferrous metal melts, parts during heat and mechanical processing.

Glass industry: Adjustment of glass-forming machines, control of temperature regimes of glass-melting furnaces.

Construction industry: Temperature control of the manufacturing process of construction materials (cement, brick, building mixtures, etc.).

THERMAL IMAGES

thermocouple

Thermocouples are two wires of different metals welded together at one end.

The thermoelectric effect was discovered by the German physicist Seebeck in the first half of the 19th century. If you connect two conductors of dissimilar metals in such a way that they form a closed circuit and maintain the contact points of the conductors at different temperatures, then a direct current will flow in the circuit. Experimentally, pairs of metals were selected that are most suitable for measuring temperature, having high sensitivity, temporary stability, and resistance to environmental influences. These are, for example, pairs of metals chromel-allumel, copper-constantan, iron-constantan, platinum-platinum / rhodium, rhenium-tungsten. Each type is suitable for solving its own problems. Chromel-alumel thermocouples (type K) have high sensitivity and stability and operate up to temperatures up to 1300 C in an oxidizing or neutral atmosphere. This is one of the most common types of thermocouples. The iron-constantan thermocouple (type J) operates in a vacuum, reducing or inert atmosphere at temperatures up to 500 C. At high temperatures up to 1500 C, platinum-platinum / rhodium thermocouples (type S or R) are used in ceramic protective covers. They perfectly measure temperature in an oxidizing, neutral environment and vacuum.

Resistance thermometers

these are resistors made of platinum, copper or nickel. These can be wirewound resistors, or the metal layer can be sprayed onto an insulating substrate, usually ceramic or glass. Platinum is most commonly used in resistance thermometers because of its high stability and linearity in resistance with temperature. Copper is used primarily for low temperature measurements, while nickel is used in inexpensive sensors for measurements in the room temperature range. For protection from the external environment, platinum resistance thermometers are placed in protective metal cases and insulated with ceramic materials such as aluminum oxide or magnesium oxide. This insulation also reduces the effects of vibration and shock on the sensor. However, along with the additional insulation, the sensor's response time to sudden temperature changes also increases. Platinum resistance thermometers are among the most accurate temperature sensors available. In addition, they are standardized, making them much easier to use. Sensors with resistance 100 and 1000 Ohm are produced as standard. The change in the resistance of such sensors with temperature is given in any thematic reference books in the form of tables or formulas. The measuring range of platinum resistance thermometers is -180 C +600 C. Despite the insulation, it is worth protecting the resistance thermometers from strong shocks and vibrations.

Thermistors.

This class of sensors exploits the effect of the change in the electrical resistance of a material with temperature. Typically, semiconductor materials are used as thermistors, as a rule, oxides of various metals. The result is sensors with high sensitivity. However, the large nonlinearity allows the use of thermistors only in a narrow temperature range. Thermistors are inexpensive and can be manufactured in miniature packages, thereby increasing the response rate. There are two types of PTC thermistors — where the electrical resistance rises as the temperature rises, and the NTC thermistors — here the electrical resistance drops as the temperature rises. Thermistors do not have a specific temperature characteristic. It depends on the specific model of the device and its area of \u200b\u200bapplication. The main advantages of thermistors are their high sensitivity, small size and weight, which make it possible to create sensors with a short response time, which is important, for example, for measuring air temperature. Of course, their low cost is also their advantage, allowing temperature sensors to be embedded in various devices. The disadvantages include the high nonlinearity of thermistors, which allows them to be used in a narrow temperature range. The use of thermistors is also limited in the low temperature range. A large number of models with different characteristics and the lack of a single standard force equipment manufacturers to use thermistors of only one specific model without the possibility of replacement.

Semiconductor sensors temperature use the dependence of the resistance of semiconductor silicon on temperature. The range of measured temperatures for such sensors is from-50 From to +150 C. Within this range, silicon temperature sensors show good linearity and accuracy. The possibility of producing in one case such a sensor not only the most sensitive element, but also amplification and signal processing circuits, provides the sensor with good accuracy and linearity within the temperature range. The non-volatile memory built into such a sensor will allow individual calibration of each device. A big plus can be called a wide variety of types of output interface: it can be voltage, current, resistance, or a digital output that allows you to connect such a sensor to a data transmission network. The weak points of silicon temperature sensors include a narrow temperature range and relatively large dimensions compared to similar sensors of other types, especially thermocouples. Silicon temperature sensors are mainly used to measure surface temperature, air temperature, especially inside various electronic devices.

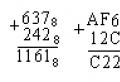

Introduction When semiconductor devices are used in electronic devices, conventions are used to unify their designation and standardize parameters. This system classifies semiconductor devices according to their purpose, basic physical and electrical parameters, constructive and technological properties, and type of semiconductor materials. The legend system for domestic semiconductor devices is based on state and industry standards. The first GOST for the designation system for semiconductor devices GOST was introduced in 1964. Then, as new classification groups of devices appeared, it was changed to GOST, and then to the industry standard OST and OST, respectively, in 1972, 1977, 1981. With this modification, the main elements of the alphanumeric code of the convention system were preserved. This designation system is logically structured and allows you to increase as the element base develops further. Basic terms, definitions and letter designations of the main and reference parameters of semiconductor devices are given in the following GOSTs: - Semiconductor diodes. Terms, definitions and parameter letters; - Field-effect transistors. Terms, definitions and parameter letters; - Bipolar transistors. Terms, definitions and parameter letters; - Thyristors. Terms, definitions, and parameter letters.

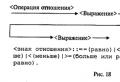

Symbols and classification of domestic semiconductor devices The designation system for modern semiconductor diodes, thyristors and optoelectronic devices is established by the OST industry standard and is based on a number of classification features of these devices. The designation system is based on an alphanumeric code, which consists of 5 elements ...

First element The first element (letter or number) denotes the original semiconductor material on the basis of which the semiconductor device is created. For devices for general civil use, letters are used that are the initial letters in the name of a semiconductor or semiconductor compound. For special applications, numbers are used instead of these letters. Starting material Legend Germanium or its compounds D or 1 Silicon or its compounds K or 2 Gallium compounds (e.g. gallium arsenide) A or 3 Indium compounds (e.g. indium phosphide) I or 4

The second element is a subclass of semiconductor devices. Usually, a letter is chosen from the name of the device, as the first letter of the name Subclass of devices Legend Subclass of devices Legend Rectifier, universal, pulse diodes D Zener diodes C Bipolar transistors T Rectifier columns Ts Field transistors P Gunn diodes B Varicaps B Current stabilizers K Thyristors high-frequency diode N Codes A Triode thyristors U Radiating OE devices L Tunnel diodes And optocouplers O

Third element. The third element (number) in the designation of semiconductor devices determines the main functionality of the device. For different subclasses of devices, the most characteristic operating parameters (functionality) are different. For transistors, this is the operating frequency and power dissipation, for rectifier diodes - the maximum forward current value, for zener diodes - the stabilization voltage and power dissipation, for thyristors - the current value in the open state.

The fifth Element. The fifth element (letter) in the alphanumeric code of the system of conventional designations indicates the sorting of individual parameters of devices manufactured in a single technology. For designation, capital letters of the Russian alphabet from A to Z are used, except for Z, O, H, Y, Sh, Sh, Z, which are similar in writing to numbers.

Symbols and classification of foreign semiconductor devices Abroad, there are various designation systems for semiconductor devices. The most common is the JEDEC designation system, adopted by the United States Electronic Instruments Technical Council. According to this system, devices are designated by an index (code, marking), in which the first digit corresponds to the number of p-n junctions: 1 - diode, 2 - transistor, 3 - tetrode (thyristor). The number is followed by the letter N and a serial number, which is registered by the Electronic Industries Association (EIA). The number may be followed by one or more letters indicating the breakdown of devices of the same type into standard sizes according to various parameters or characteristics. However, the serial number digits do not identify the type of source material, frequency range, power dissipation, or application. In Europe, a system is used by which semiconductor designations are assigned by the Association International Pro Electron. According to this system, appliances for household appliances of widespread use are designated by two letters and three numbers. So, for devices of wide use, after two letters there is a three-digit serial number from 100 to 999. For devices used in industrial and special equipment, the third character is a letter (letters are used in reverse alphabetical order: Z, Y, X, etc.) ) followed by a sequence number from 10 to 99.

First element. The first element (letter) designates the original semiconductor material on the basis of which the semiconductor device is created. The 4 Latin letters A, B, C and D are used, according to the type of semiconductor or semiconductor compound. Initial material Band gap, eV Legend Germanium 0.6 ... 1 A Silicon1 ... 1.3 V Gallium arsenide more than 1.3 C Indium antimonide less than 1.6 D

The second element (letter) designates a subclass of semiconductor devices. The third element (number or letter) in the alphanumeric code designates semiconductor devices intended for general civilian use (number) or for special purpose equipment (letter). In the latter case, capital Latin letters are used as a letter, consumed in the reverse order Z, Y, X, etc. The fourth element (2 digits) means the serial number of the technological development and varies from 01 to 99. For example, VTX is a special purpose silicon controlled rectifier (thyristor) with registration number 10 and voltage 200 V.

JIS-C-7012 Standard The system of standard designations developed in Japan (JIS-C-7012 standard, adopted by the EIAJ-Electronic Industries Association of Japan) allows you to determine the class of a semiconductor device (diode or transistor), its purpose, and the type of semiconductor conductivity. The type of semiconductor material is not reflected in the Japanese system. The JIS-C-7012 semiconductor symbol consists of five elements. First element. The first element (number) indicates the type of semiconductor device. 3 digits (0, 1, 2 and 3) are used according to the type of instrument. Second element. The second element is designated by the letter S and indicates that this device is a semiconductor device. The letter S is used as the initial letter for Semiconductor. Third element. The third element (letter) designates a subclass of semiconductor devices. The following table lists the letters used to denote the subclasses of the Fourth Element. The fourth element denotes the registration number of the technological development and begins with the number 11. The fifth element. The fifth element reflects the development modification (A and B are the first and second modifications).

JEDEC The JEDEC (Joint Electron Device Engineering Council) designation is adopted by the United States' Joint Electron Device Engineering Council. According to this system, devices are designated by an index (code, marking), in which: First element. The first element (digit) indicates the number of p-n transitions. 4 digits (1, 2, 3 and 4) are used in accordance with the type of device: 1 - diode, 2 - transistor, 3 - thyristor, 4 - optocoupler. Second element. The second element consists of the letter N and a serial number, which is registered by the Electronic Industries Association (EIA). The serial numbers do not identify the type of source material, frequency range, power dissipation, and application. Third element. The third element - one or more letters, indicate the breakdown of devices of the same type into standard sizes according to different characteristics. A manufacturer whose parameters are similar to those registered by the EIA may present their instruments with the JEDEC designation. Example: 2N2221A, 2N904.

Graphic designations and standards In technical documentation and special literature, conventional graphic designations of semiconductor devices are used in accordance with GOST “Designations, graphic in diagrams. Semiconductor devices ".

Symbols of electrical parameters and comparative reference data of semiconductor devices For semiconductor devices, the values \u200b\u200bof the main electrical parameters and the limiting operational characteristics are determined and standardized, which are given in the reference books. These parameters include: voltage (for example, Upr - constant forward voltage of the diode), current (for example, Ist, max - the maximum allowable current in the stabilization of a zener diode, power (for example, Pout - the output power of a bipolar transistor), resistance (for example, rdif - differential resistance of the diode), capacitance (for example, Ck - capacitance of the collector junction), time and frequency (for example, tvos, arr - reverse recovery time of a thyristor, diode), temperature (for example, Tmax - maximum ambient temperature). parameters are estimated in the hundreds, and for each subclass of semiconductor devices these parameters will be different. References give the values \u200b\u200bof the main electrical parameters and the limiting performance of semiconductor devices. Below are examples of these data for typical representatives of different types of devices.

Examples of the designation of some transistors: KT604A - silicon bipolar, medium power, low frequency, development number 04, group A 2T920 - silicon bipolar, high power, high frequency, development number 37, group A 2PS202A-2 - a set of low-power silicon field-effect transistors of medium frequency, number development 02, group A, packageless, with pigtails on a crystal holder. 2D921A - silicon pulse diode with an effective life time of minority charge carriers less than 1 ns, development number 21, group A 3I203G - arsenide gallium tunnel generator diode, development number 3, group G AD103B - arsenide gallium emitting diode of infrared range, development number 3, group B.

Main GOSTs: GOST Semiconductor devices. Terms and definitions OST, Semiconductor devices. System of symbols. GOST 2, Graphic symbols in diagrams. Semiconductor devices GOST Semiconductor devices. Basic dimensions of GOST Bipolar transistors. Terms, definitions, and parameter letters. GOST Field-effect transistors. Terms, definitions, and parameter letters. GOST Semiconductor infrared emitting devices. Basic dimensions. GOST Semiconductor diodes. Terms, definitions, and parameter letters.